Your Vision Is Our Mission

About us

With over 25 years of experience in the CNC machining industry, Vision Machining focuses on precision and efficiency. Our advanced automation technology allows us to handle high-volume production, offering competitive pricing while maintaining quality.

In addition to CNC machining, we have substantial expertise in welding, sheet metal fabrication, and related fields. This enables us to provide comprehensive solutions tailored to your specific needs. We are committed to excellence and innovation, ensuring that your projects are completed with precision and reliability.

HSEQ

At Vision Machining, we are dedicated to maintaining high standards in Health, Safety, Environment, and Quality (HSEQ). Our quality control processes ensure that every product meets precise specifications and industry standards. We prioritize the health and well-being of our employees by providing a safe and supportive work environment. Our operations aim to minimize environmental impact through sustainable practices and waste reduction. Safety is integral to our operations, with measures in place to protect our team and maintain a secure workplace. Through our HSEQ initiatives, we strive for excellence and sustainability in all aspects of our business.

Services

At Vision Machining, we excel in both prototyping and mass production. Our advanced CNC machining capabilities, honed through the internal production of our own product line, ensure precision, quality, and efficiency at every stage. Whether you need a single prototype to bring your design to life or require large-scale manufacturing for high-volume production, our setup is optimized to deliver the perfect solution tailored to your specific needs.

Our Vision

To be recognized as an industry leader in CNC machining, known for our quality, reliability, and technological innovation. We aim to continuously invest in cutting-edge technologies and expand our capabilities to serve a diverse range of industries worldwide.

Parts

Machine Park

DMG Mori NTX 3000 | 3000

Mill-Turn

• Max. turning diameter: Φ670mm.

• Max. turning length: 3,125mm.

• Max. swing of workpiece: Φ700mm.

• Swing over cross slide: Φ700mm.

• Max. distance between centers: 3,312mm.

Features:

• Simultaneous 5-axis machining.

• Automatic steady rest (75-430mm Dia.).

• High Pressure Coolant (70 Bar).

• Dual spindle.

• Coolant chiller.

Mill-Turn

• Max. turning diameter: Φ430mm.

• Max. turning length: 800mm.

• Max. workpiece weight: 250kg.

• Bar work capacity: Φ73mm.

Features:

• Simultaneous 5-axis machining.

• Lower turret.

• Dual spindle.

• Workpiece unloader.

• Bar feeder.

• High Pressure Coolant (70 Bar).

• Coolant chiller.

DMG Mori NTX 1000

Vertical Mill

• X-axis: 762mm.

• Y-axis: 406mm.

• Z-axis: 508mm.

• Spindle nose to table (~ max): 610mm.

• Spindle nose to table (~ min): 102mm.

• Max weight on platter: 680kg.

+Robot (Universal Robots UR30).

• Max payload: 10-30kg.

Or

+Robot (Universal Robots UR10e).

• Max payload: 5kg.

+4th Axis available.

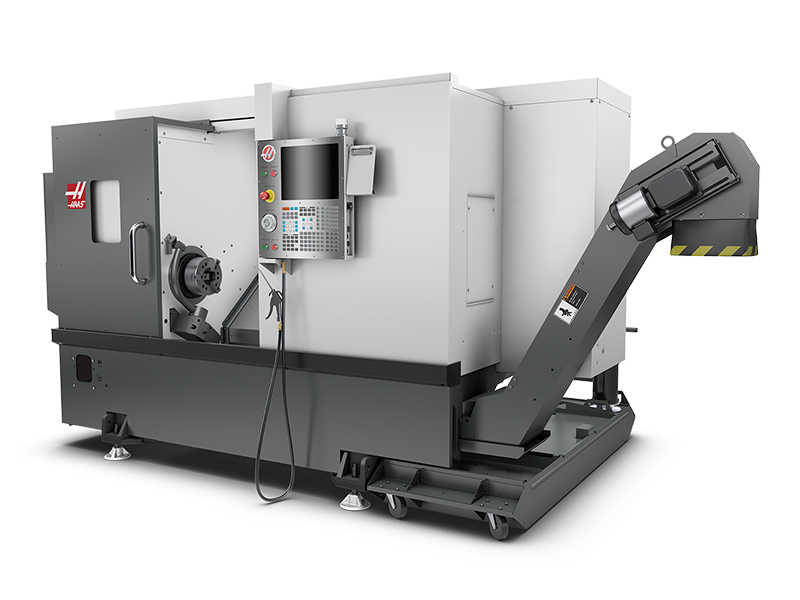

Haas VF-2SS

Haas VF-2SS

Vertical Mill

• X-axis: 762mm.

• Y-axis: 406mm.

• Z-axis: 508mm.

• Spindle nose to table (~ max): 610mm.

• Spindle nose to table (~ min): 102mm.

• Max weight on platter : 680kg.

+Robot (Kassow Robots KR1410).

• Max payload: 5kg.

+4th axis available.

Integrated Full 5-Axis

• X-Axis: 381mm.

• Y-Axis: 356mm.

• Z-Axis: 305mm.

• Spindle nose to table (~ max): 406mm.

• Spindle nose to table (~ min): 102mm.

• B-Axis Tilt: 120° to -45°.

• Max weight on platter: 45.4kg.

+Robot (FANUC LR Mate 200i D/7L 6-axis robot arm).

• Max payload: 4kg.

Haas UMC-350HD

Haas UMC-750

Integrated Full 5-Axis

• X-Axis: 762mm.

• Y-Axis: 508mm.

• Z-Axis: 508mm.

• Spindle nose to table (~ max): 610mm.

• Spindle nose to table (~ min): 102mm.

• B-axis Tilt: 120° to -35°.

• Max weight on platter: 300kg.

+Robot (Universal Robots UR30).

• Max payload: 10-30kg.

Or

+Robot (Universal Robots UR10e).

• Max payload: 5kg.

Haas UMC-1000SS

Integrated Full 5-Axis

• X-Axis: 1016mm.

• Y-Axis: 635mm.

• Z-Axis: 635mm.

• Spindle nose to table (~ max): 737mm.

• Spindle nose to table (~ min): 102mm.

• B-Axis Tilt: 120° to -35°.

• Max weight on platter: 454kg.

+Robot (FANUC M-20iD/35 6-axis robot arm).

• Max payload: 27kg.

Haas ST20Y

Lathe

• Chuck size: 210mm.

• Max part swing: 533mm.

• Max cutting diameter: 298mm.

• Max cutting length: 572mm.

• Bar capacity: 51mm.

+Bar Feeder.

• Bar diameter: 10mm to 51mm.

Contact us!

Reach out to us with your requirements, and we will promptly respond with our most competitive pricing and fastest delivery time. Let us help you achieve the perfect solution for your CNC machining needs.